Doosan Enerbility is embarking in earnest on the development of aircraft engines using the expertise it acquired from developing gas turbines for power generation.

On March 27th, Doosan Enerbility announced that it had added “manufacturing of aircraft engines and propulsion auxiliary systems, maintenance, sales and services” in the company’s business objectives upon passing of the proposed agenda item at the general shareholders’ meeting on March 26th. Prompted by this recent development, the company will now expedite its efforts to develop engines for aircrafts, particularly unmanned aerial vehicles.

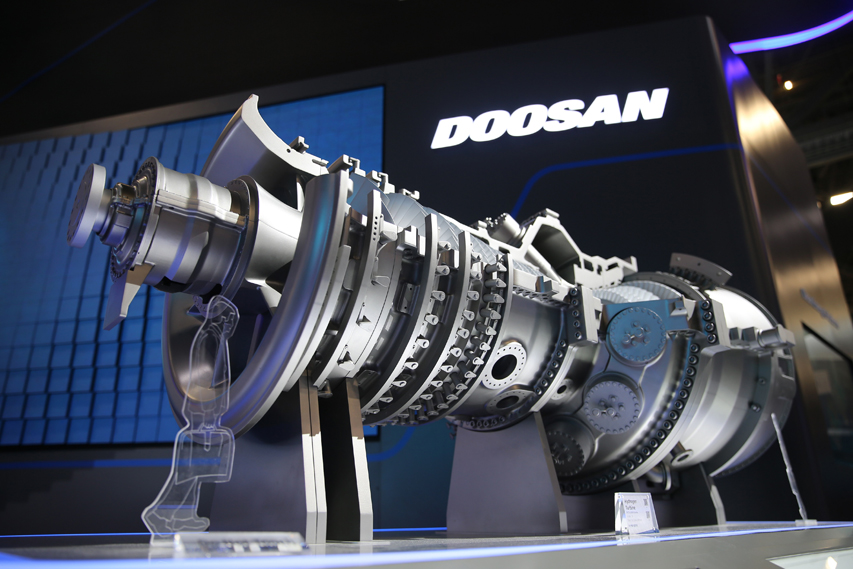

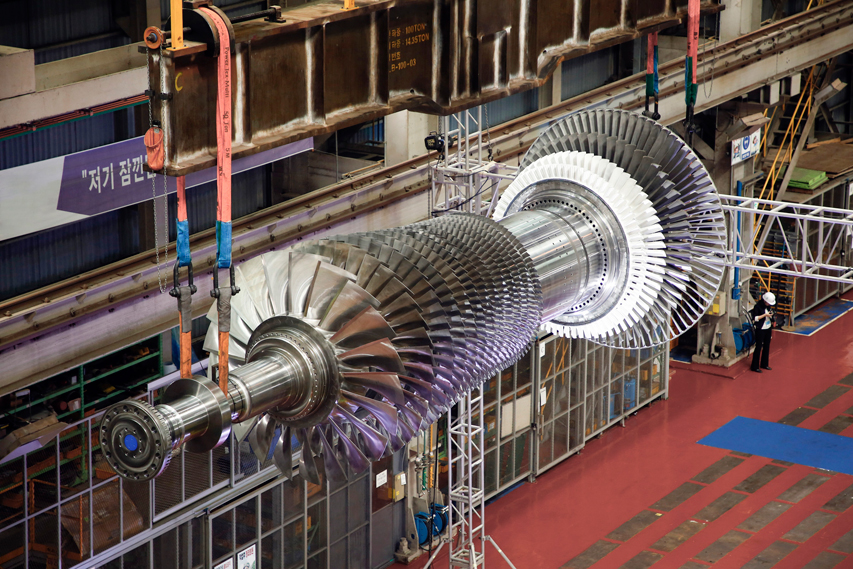

The fundamental technology applied to gas turbines for power generation, which Doosan Enerbility had managed to successfully develop, is the same as the technology applied to aircraft engines, and the structure and operating principles are similar as well. The key elements of aircraft gas turbines, which are used to secure the forward thrust needed to propel the aircraft, are high power, lightness and operating flexibility. The difference lies in that gas turbines for power generation require high efficiency, high power and stability, and are larger in size compared to the gas engines of aircrafts.

Doosan Enerbility plans to apply the expertise and know-how it holds in the areas of design, manufacturing and materials technology, which it acquired from the process of developing the large-size gas turbine for power generation, in the development of aircraft engines. Aircraft engines require the technology for withstanding the ultra-high temperature of 1500°C when igniting the engine. Doosan already holds cooling and coating technology that makes it possible to withstand ultra-high temperature that can reach up to 1680°C. Moreover, the company also holds several competitive advantages –the capability to develop key materials such as hot parts, various intellectual property rights and a database built during the course of the development process, its own design and manufacturing capabilites and testing infrastructure, not to mention upgraded engineering capabilities.

Doosan’s foray into the aircraft engine business has already started. The company is currently participating in the “10,000 lbf* gas turbine engine development for unmanned aerial vehicles,” a project led by the Agency for Defense Development. The project consists of a total of three initiatives, with Doosan Enerbility taking on two of the initiatives deemed as being the most challenging and involving key technologies. Doosan will be leading the “engine layout design and components analysis” and the “casting & forging of turbine vanes/blades and post-processing” initiatives, with the aim to complete the basic design by 2027. Doosan is also working on the conceptual design of an advanced aircraft engine**, a work that was commissioned by the Korean government in an effort to secure Korea’s own fighter jet engine technology.*10,000lbf (thrust of 10 thousand pound-force)** Advanced aircraft engine technology is regarded as being a critical technology from both the economical and national security perspective, as made evident in how it has been included in the Ministry of Science and ICT’s Top 12 National Strategic Technologies and the Ministry of National Defense’s Top 10 Strategic Technologies for National Defense.

“Our experience as an original equipment manufacturer that has developed, manufactured and supplied gas turbines for power generation, along with our physical infrastructure and manpower, lie at the source of Doosan’s competitiveness,” said Seungwoo Sohn, CEO of Doosan Enerbility’s Power Services Business Group. “We plan to make active use of this to help make it possible to manufacture aircraft engines locally, as well as lay the groundwork for venturing into the wider global market.”